Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Introduction to MPM Printer SMT

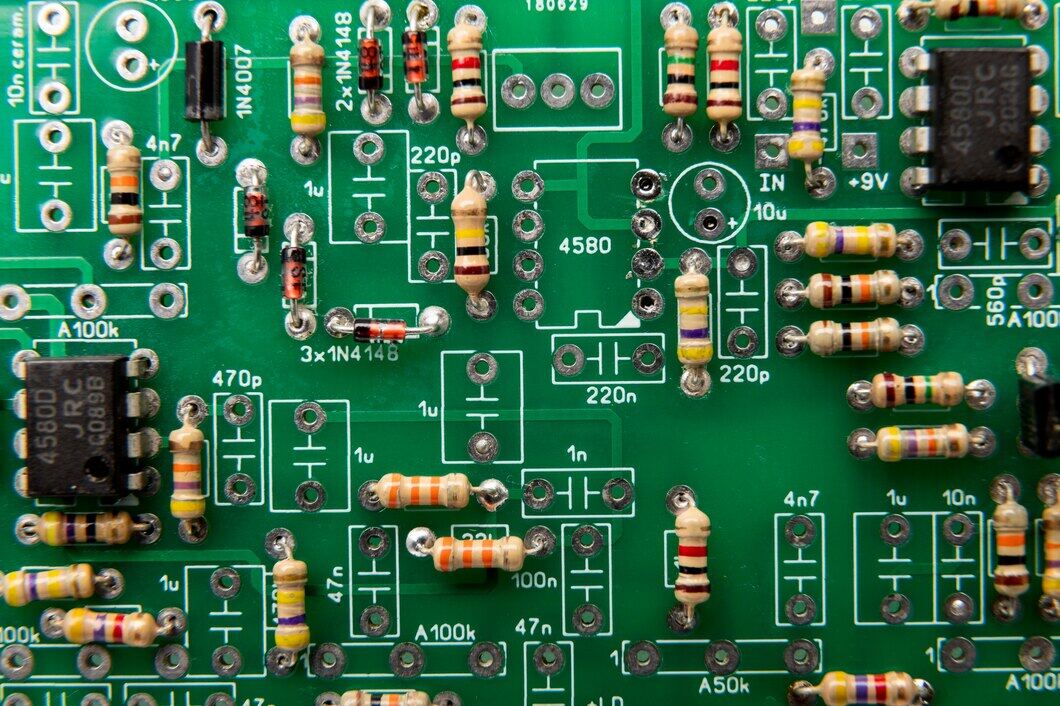

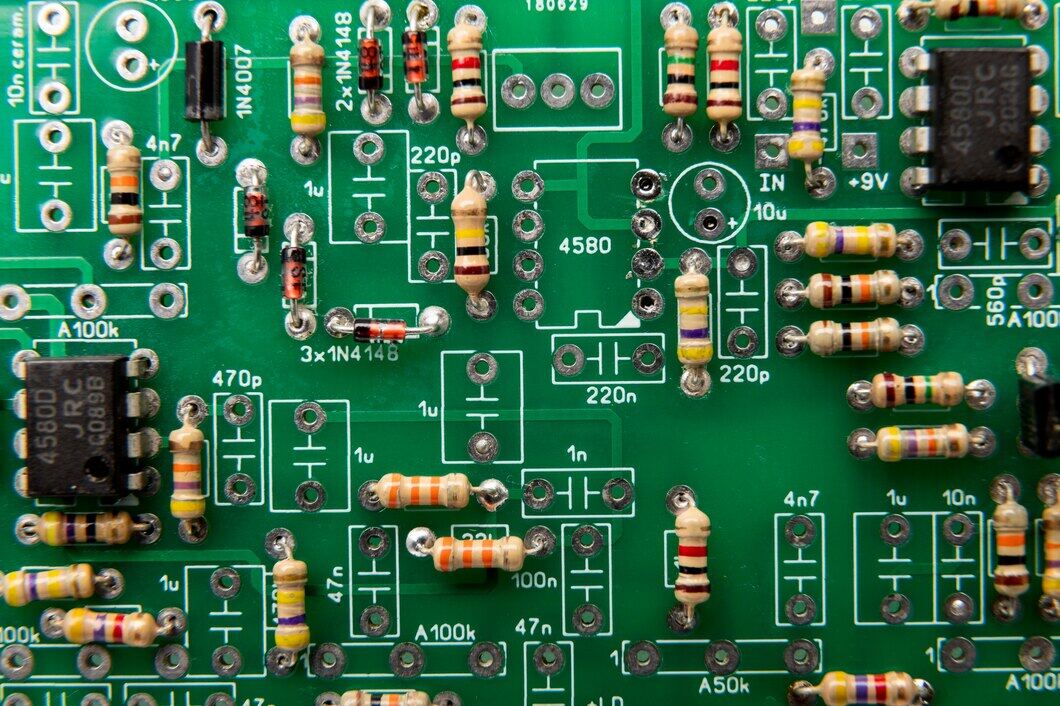

In the world of electronics manufacturing, precision is a key factor. Efficiency is another key factor. These factors determine the success of production lines. One crucial component exists in the Surface Mount Technology (SMT) process. This component is the solder paste printing stage. Accuracy in this stage directly impacts the quality of the final product. MPM Printer SMT solutions come into play here. These solutions offer industry-leading performance. They also provide reliability. We are a trusted manufacturer. We are also a partner in the SMT industry. We understand the importance of delivering high-quality solutions. These solutions must meet the demands of modern electronics production.

Why Solder Paste Printing Matters in SMT

Solder paste printing is the foundation. It supports the entire SMT assembly process. It involves applying a precise amount of solder paste. This paste is applied onto a printed circuit board (PCB). The application happens before components are placed. The components are then soldered. A small error in this stage can lead to defects. These defects include bridging. They also include insufficient solder. Misalignment is another possible defect. These issues ultimately affect product functionality. They also impact reliability.

MPM Printer SMT systems are designed to eliminate these issues. They offer cutting-edge stencil printing technology. This technology ensures consistent solder deposition. It also guarantees accurate solder deposition. This translates into higher yields. It reduces rework. It lowers overall production costs.

The Advantages of MPM Printer SMT

When selecting a solder paste printer for an SMT line, manufacturers must consider factors. These factors include accuracy. Speed is another factor. Automation is important. Ease of use is also critical. Our MPM Printer SMT solutions stand out. This is due to several key advantages:

Precision Engineering for High-Quality Printing

MPM printers utilize advanced vision alignment systems. They also use precision print heads. These features achieve industry-leading accuracy. This ensures every PCB receives the exact amount of solder paste. The paste is applied in the right location. This reduces the risk of defects. It improves overall yield.

Automated Features for Increased Efficiency

Automation is a game-changer in SMT manufacturing. MPM printers come equipped with automated features. These include self-cleaning systems. Automatic stencil alignment is another feature. Real-time monitoring is also included. These enhancements boost efficiency. They minimize downtime. This automation allows manufacturers to maintain high throughput. Quality is not sacrificed.

User-Friendly Interface for Seamless Operation

Even advanced technology should be easy to operate. Our MPM Printer SMT models feature intuitive software interfaces. These interfaces simplify setup. They also simplify operation. This reduces the learning curve for operators. It ensures consistent performance. Performance remains stable across different production shifts.

Robust Build Quality for Long-Term Reliability

Durability is essential in high-volume manufacturing environments. MPM printers are built with high-quality materials. They are engineered for long-term reliability. This ensures stable operation. Stability is maintained even in demanding production settings.

Versatility for Different PCB Sizes and Configurations

Electronic devices are becoming increasingly complex. SMT manufacturers require flexibility in production lines. Our MPM printers accommodate a wide range of PCB sizes. They also handle various configurations. This makes them suitable for diverse applications. Applications range from consumer electronics to automotive devices. Medical devices are also included.

How MPM Printer SMT Enhances Your Production Line

Integrating an MPM Printer into your SMT line offers benefits. These benefits go beyond high-quality printing. Here’s how it improves your manufacturing process:

Improved Yield and Reduced Defects

Precise solder paste application is ensured by MPM printers. This helps eliminate defects. Defects like insufficient solder are avoided. Bridging is also minimized. This leads to fewer rework requirements. Scrap costs are reduced.

Higher Throughput and Shorter Cycle Times

High-speed printing capabilities exist in these printers. Automated processes are also included. Manufacturers can achieve faster production cycles. Consistent quality is maintained.

Reduced Maintenance and Downtime

MPM printers have self-cleaning features. Automated maintenance is another feature. These contribute to lower maintenance requirements. Machine downtime is reduced. Production lines run smoothly.

Scalability for Future Growth

Production demands may grow. MPM printers offer scalable solutions. These solutions integrate with Industry 4.0 technologies. Smart manufacturing becomes possible. Data-driven optimization is enabled.

Choosing the Right MPM Printer SMT for Your Needs

Selecting the right MPM Printer SMT model depends on your requirements. Consider these factors:

Production Volume: High-volume manufacturers benefit from advanced models. These models have higher throughput. Automation features are enhanced.

PCB Complexity: Complex PCBs may have fine-pitch components. Precision becomes critical. Alignment capabilities are a top priority.

Budget and ROI: Investing in an MPM printer is a long-term decision. Evaluate return on investment. Improved efficiency contributes to ROI. Reduced defects also matter.

Our team of experts is here to help. We assist in choosing the best MPM printer for your SMT line. Performance is balanced. Cost is considered. Long-term reliability is ensured.

Partner with Us for SMT Success

We are committed to providing top-tier MPM Printer SMT solutions. These solutions empower manufacturers. Excellence in surface mount assembly is achieved. You may want to enhance your existing production line. Alternatively, you might set up a new one. Our team is ready to assist. Expert guidance is provided. Technical support is offered. Innovative solutions are tailored to your needs.

By choosing an MPM printer, you invest in the future. This future includes high-quality manufacturing. Efficiency is guaranteed. Reliability is a hallmark. Contact us today. Learn more about our MPM Printer SMT solutions. Take your production to the next level.