Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

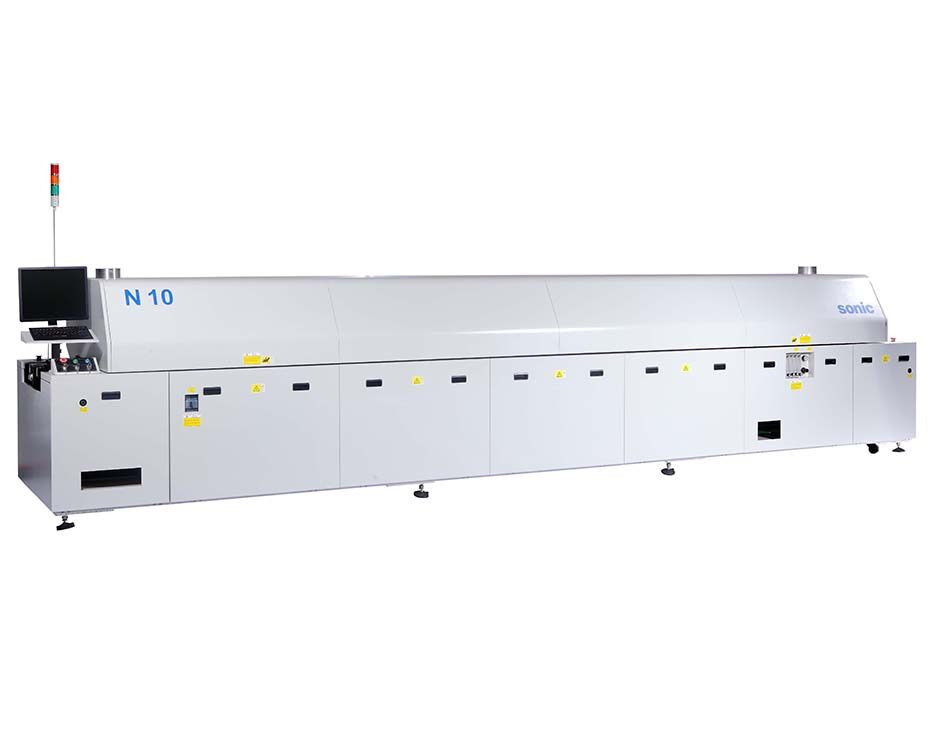

SONIC SMT Reflow Soldering Oven is the perfect choice for lead-free reflow soldering. With a simple interface and an information center, it ensures easy operation and provides the best performance. Moreover, it has the lowest power consumption in its class for maximum energy efficiency. Get this oven and enjoy the best SMT reflow soldering experience.

|

Model |

K2-1003N-400 |

K2-1303N-400 |

K2-1003N-700 |

K2-1303N-700 |

|

Heating system |

||||

|

Heating zone |

Up 10 Down 10 |

Up 13 Down 13 |

Up 10 Down 10 |

Up 13 Down 13 |

|

Cooling zone |

3 |

|||

|

Effective heating length |

3740mm |

4830mm |

3740mm |

4830mm |

|

Range of temperature setting |

RT-350℃ |

|||

|

Exhaust Volume |

10-12m³/min x 2pcs |

|||

|

Temperature Control |

PID+PLC |

|||

|

Accuracy of Temperature Control |

±1℃ |

|||

|

Control System |

||||

|

Control Interface |

WINDOWS 10 professional |

|||

|

Control Unit |

PID+PLC |

|||

|

N2 Automatic Control System |

PID adjustment + closed-loop control |

|||

|

Track Width Automatically Adjust |

PID+PLC |

|||

|

Temperature Real-Time Monitor |

ARM Real-time temperature monitoring system |

|||

|

Conveyor System |

||||

|

PCB Conveyor |

Trail+Chain(Option:Center Support) |

|||

|

PCB Working Width |

50-40omm/50~700mm/50-300mm*2pcs |

|||

|

PCB Board Clearance |

+30mm/-25mm |

|||

|

Conveyor Speed |

200-2000mm/min |

|||

|

Conveyor Height From Floor |

900±20mm |

|||

|

Electrical System |

||||

|

Power |

3phase, 5-wire, AC380v or 3Phase, 4wire, AC220V |

|||

|

Starting Power Rating |

40kw |

60kw |

45kw |

60kw |

|

Normal Power Rating |

12-14KW |

15-18KW |

13-15KW |

15-19KW |

|

Nitrogen System |

||||

|

N2 cooling system |

K2/K3 series full area nitrogen filling, the whole area sampling selection N Series All Zone Nitrogen Filling, Sample Option |

|||

|

Cooling System |

K2/K3 Series optional built-in/External, A series waterless cooling system N Series can choose Internal Or External |

|||

|

Dimensions |

||||

|

LxWxH(mm) |

6200x1230x1525 |

7280x1230x1515 |

6200x1606x1525 |

7280X1610×1515 |

|

Weight |

Approx:3000kg |

Approx:3200kg |

Approx:3500kg |

Approx:3900kg |

Features of Products

1. Simple interface and information center

SONIC reflow utilized a premium computer with Windows Software, a keyboard, and a VGA color monitor. Our new, easy-to-learn, user-friendly process control program displays all operating conditions and parameter data just like an information center.

2. Lowest power consumption

High thermal efficiency makes the power consumption, realizing the desire for high-efficiency production with low power consumption, lower by 15%-20% than the other brand's reflow.

3. Highest repeatability and lowest ∆t, meet the lead-free process

After 9 sets of limit tests of L350xW300xH10mm entering the furnace at the same time, it is concluded that the temperature difference between the empty and full load of our reflow oven is within 1℃.

4. Auto China-rail lubrication system

Our advanced automatic chain-rail lubrication system eliminates the mass and maintenance associated with keeping the 1.5mg/min lubricant supply. Also, the lubrication cycle can be programmable by the operator. The lubrication system can actively lubricate the chain and guide rails, meeting the demand for immediate lubrication, with stable flow rate, active oil supply, and immediate lubrication. It can also be set and managed on a computer, without the need for manual maintenance.

5. Easy maintenance

SONIC cooling system is lower maintenance. SONIC’s heat exchange and air cooling filter are divided design, both can be discharged directly from the machine, SONIC is able to achieve maintenance based on nonstop production.

6. Flux flow control

SONIC flux flow control can solve the messy filter and touch cleaning problems based on an effective flux removal system and quick cleaning, then reducing the system maintenance and cleaning.

7.New-designed conveyor system

Roller-designed chain lower down the friction between rail and chain, also lower the tensile force which is press on the rail then to prevent the rail become wrapped and deformed.

8.Patented 3-phases electric current balanced heater

SONIC 3-phases electric current balanced heaters offer low current shock, and offer high thermal compensation. Besides, the balanced heater has a large heat exchange area and fast temperature compensation; The heating wire has a large distance, reducing the accumulation of heat energy and extending the lifespan of the heater.