Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

In today's fast-paced world of electronics manufacturing, achieving precision, efficiency, and reliability is paramount. Surface Mount Technology (SMT) equipment lies at the heart of this endeavor, offering the tools and technologies needed to assemble electronic components onto printed circuit boards (PCBs) with unparalleled accuracy. In this extensive guide, we'll delve deeper into the realm of surface mount technology SMT equipment, exploring its myriad components, intricate functionalities, and best practices for optimizing production processes.

Unveiling the Essence of Surface Mount Technology (SMT)

Navigating Through Surface Mount Technology (SMT)

Surface Mount Technology (SMT) represents a paradigm shift in electronic assembly, transcending the limitations of traditional through-hole technology. By mounting components directly onto the surface of the PCB, SMT enables higher component density, reduced board size, and enhanced electrical performance. This revolutionary approach has become the cornerstone of modern electronics manufacturing, driving innovation and pushing the boundaries of what's possible.

Deciphering the Role of Surface Mount Technology SMT Equipment

At the heart of the SMT revolution lies a diverse array of equipment meticulously designed to automate and streamline the assembly process. From pick-and-place machines to stencil printers, reflow ovens, and inspection systems, each component of SMT equipment plays a pivotal role in ensuring the seamless integration of electronic components onto PCBs.

Dissecting the Components of Surface Mount Technology SMT Equipment

Harnessing the Power of Pick-and-Place Machines

Pick-and-place machines serve as the workhorses of SMT assembly, orchestrating the precise placement of components onto PCBs with unparalleled accuracy. These sophisticated machines employ a combination of vacuum nozzles, vision systems, and intricate algorithms to pick components from reels or trays and position them onto designated locations on the board. The seamless integration of speed, precision, and reliability makes pick-and-place machines indispensable assets in modern electronics manufacturing.

Unveiling the Art of Stencil Printing

Stencil printers play a crucial role in the SMT assembly process, laying the foundation for solder paste deposition with surgical precision. Utilizing metal stencils adorned with meticulously crafted apertures, these printers dispense solder paste onto the PCB, ensuring optimal pad coverage and alignment. The art of stencil printing lies in achieving the perfect balance between tension, alignment, and solder paste viscosity, culminating in flawless solder joints and robust electrical connections.

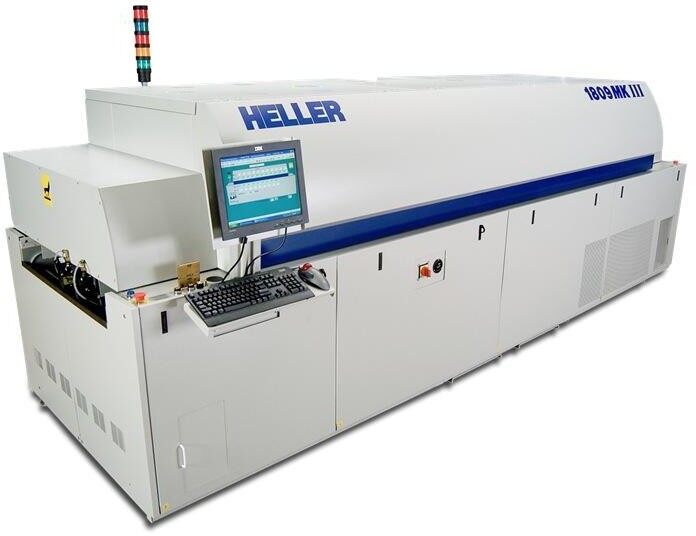

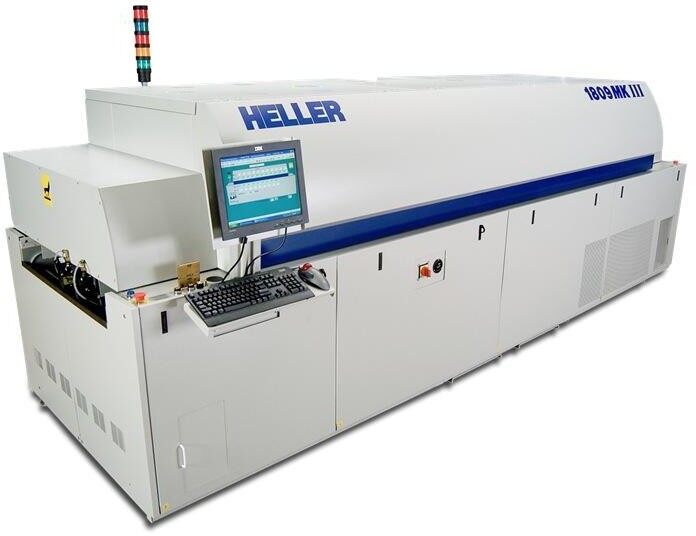

Embracing the Heat of Reflow Ovens

Reflow ovens serve as the crucibles where solder paste transforms into resilient solder joints, binding components to PCBs with unwavering strength. Guided by meticulously crafted reflow profiles, these ovens subject PCBs to a carefully choreographed dance of temperature gradients, coaxing solder paste to undergo its metamorphic journey from paste to solid. The symphony of heat, time, and atmosphere orchestrates a ballet of solder reflow, ensuring the integrity and reliability of assembled PCBs.

Illuminating the Path with Inspection Systems

Inspection systems serve as the vigilant guardians of quality assurance, meticulously scrutinizing every facet of assembled PCBs to detect imperfections and defects. Armed with advanced technologies such as automated optical inspection (AOI) and X-ray inspection, these systems unveil the hidden secrets of solder joints, component placement, and board quality. The relentless pursuit of perfection drives the evolution of inspection systems, ensuring that only the finest specimens emerge from the crucible of electronic assembly.

Elevating Surface Mount Technology SMT Equipment Performance to New Heights

Nurturing Through Calibration and Maintenance

The quest for peak performance begins with the meticulous calibration and maintenance of surface mount technology SMT equipment, ensuring that every component operates at its zenith. From fine-tuning vision systems to aligning nozzles and optimizing reflow profiles, meticulous attention to detail lays the foundation for flawless execution. Regular maintenance rituals, including cleaning, lubrication, and component replacement, safeguard against the ravages of time, ensuring that SMT equipment remains in prime condition for years to come.

Charting the Course with Process Optimization

Process optimization serves as the North Star guiding manufacturers towards the pinnacle of efficiency and quality. By fine-tuning pick-and-place programs, solder paste deposition parameters, and reflow profiles, manufacturers unlock new realms of productivity and precision. The relentless pursuit of perfection drives continuous improvement initiatives, propelling manufacturing processes towards ever-greater heights of excellence.

Cultivating a Culture of Training and Skills

Development

The human element remains the linchpin of SMT equipment operation, with skilled operators and technicians serving as the custodians of precision and reliability. Rigorous training programs and skills development initiatives empower operators to master the intricacies of SMT equipment, fostering a culture of excellence and expertise. Continuous learning ensures that operators remain at the vanguard of technological advancement, driving innovation and pushing the boundaries of what's possible.

Embarking on a Journey of Technological Advancement

Embracing the Dawn of Industry 4.0 Integration

The advent of Industry 4.0 heralds a new era of interconnectedness and intelligence in electronic manufacturing, with SMT equipment poised to embrace the winds of change. IoT-enabled sensors, predictive maintenance algorithms, and data analytics tools converge to create a symphony of efficiency and insight, propelling manufacturing processes towards unprecedented levels of productivity and autonomy. The fusion of human ingenuity and technological prowess ushers in a new era of innovation and opportunity, empowering manufacturers to chart a course towards a brighter, more interconnected future.

Pioneering the Frontier of Emerging Technologies

The horizon of surface mount technology SMT equipment brims with promise and potential, with emerging technologies poised to redefine the boundaries of what's possible. Robotic assembly systems, 3D printing of electronic circuits, and machine learning algorithms stand ready to revolutionize electronic manufacturing, ushering in an era of unparalleled efficiency and flexibility. The relentless march of progress fuels the fires of innovation, propelling manufacturers towards new frontiers of possibility and prosperity.

Navigating the Path Forward

Cultivating Sustainable Manufacturing Practices

In an age of increasing environmental consciousness, sustainability emerges as a guiding principle in electronic manufacturing. From eco-friendly materials to energy-efficient processes and waste reduction strategies, manufacturers embrace the imperative of sustainability, forging a path towards a greener, more sustainable future. The fusion of sustainability and innovation drives the evolution of SMT equipment, ensuring that progress marches hand in hand with environmental stewardship.

Conclusion: Forging a Path Towards Excellence

Surface Mount Technology (SMT) equipment stands as a testament to human ingenuity and technological prowess, enabling the precise, efficient, and reliable assembly of electronic components onto printed circuit boards (PCBs). From pick-and-place machines to reflow ovens and inspection systems, each component of SMT equipment plays a vital role in the symphony of electronic assembly, ensuring that every PCB emerges as a masterpiece of precision and reliability.

As manufacturers navigate the ever-changing landscape of electronic manufacturing, SMT equipment serves as their trusted companion, guiding them towards the pinnacle of excellence and innovation. By embracing emerging technologies, cultivating sustainable practices, and nurturing a culture of continuous improvement, manufacturers unlock new realms of possibility and opportunity, propelling electronic manufacturing towards a brighter, more interconnected future.

In the crucible of electronic assembly, SMT equipment stands as a beacon of excellence, illuminating the path towards a world where precision, efficiency, and reliability reign supreme. As manufacturers embark on their journey towards excellence, they do so with the unwavering confidence that, with the right tools, technologies, and vision, anything is possible.